Industrial All-in-One Machines PC: Intelligent Sorting and Precise Inventory Management

Industry Trends 2025-10-07

In today’s era of rapid e-commerce development and increasingly stringent requirements for supply chain response speed, warehouse and logistics centers have transformed from traditional “storage locations” to highly efficient and information-intensive “order fulfillment centers”. Efficiency and accuracy have become the key indicators for measuring their core competitiveness. During this transformation process, industrial all-in-one machines, as sturdy and reliable information terminals and control cores, are deeply integrated into various aspects such as intelligent sorting, inventory tracking, and warehouse automation, providing a powerful technical engine for the efficient operation of modern warehouse logistics.

Mobile Work Terminal: Making Information “Move with You”

In large warehouses, workers need to walk several kilometers every day to perform tasks such as shelving, picking, verification, and inventory counting. How to ensure that information reaches every mobile worker in real time and accurately is the key to improving efficiency. Industrial all-in-one machines, with their diverse forms, perfectly solve this problem.

Vehicle-mounted Terminal: Forklifts are an important transportation tool in warehouses. By installing a sturdy industrial all-in-one machine on a forklift, it becomes a mobile information workstation. Through a wireless network connection to the warehouse management system (WMS), the forklift driver can directly receive task instructions, such as “Move the pallet at position 4 on shelf A to the 5th platform of the B shipping area”. The system will plan the driver’s route and clearly display the location information on the screen. By linking with the bar code scanner or RFID reader on the vehicle, the driver only needs to scan the pallet or location label to confirm the operation in real time, and the data will be automatically uploaded to the WMS. This “paperless, navigational” intelligent sorting not only eliminates human errors in recording and misplacing goods, but also eliminates the circulation and manual entry of paper documents, greatly improving operational efficiency and accuracy.

Mobile Terminal for Picking Trucks: For the picking of scattered orders, industrial all-in-one machines can be installed on hand-pushed picking trucks. It receives the picking task list from the WMS and intelligently plans a path for the picker in the form of a “task list” or “electronic map”, avoiding back-and-forth movement between large shelves. Every time it reaches a shelf, the screen will clearly display the picture, name, and quantity of the required goods. The picker confirms by scanning the barcode, and the system will automatically verify. If there is an error, it will immediately prompt. This “paperless, navigational” intelligent picking not only reduces labor intensity but also reduces the error rate of picking to *%.

Guardian of Precise Inventory Tracking

Precise inventory is the foundation of warehouse management and the key to avoiding overstocking or stockouts. Industrial all-in-one machines are the core tool for real-time and precise inventory tracking.

Data Collection Points: Whether fixed at the entry and exit points, conveyor belt nodes, or mobile on forklifts and picking trucks, industrial all-in-one machines are the hub for data collection. They connect various automatic identification devices (bar code scanners, RFID readers, visual cameras, etc.) and are responsible for parsing and processing the collected information. When a batch of goods is入库, the industrial all-in-one machine reads its identity information and compares it with the purchase order in the WMS to confirm without error, then it guides it to be shelved at the designated location. When the order is picked or the goods are dispatched, it also records the flow of each item. This real-time data collection throughout the entire process of入库, shelving, transfer, and picking and dispatching ensures that the inventory data in the WMS system is always highly consistent with the physical inventory.

Powerful Tool for Dynamic Inventory Counting: Traditional periodic shutdown inventory counts are time-consuming and labor-intensive and affect normal operations. With the help of industrial all-in-one machines, enterprises can achieve dynamic inventory counting or circular inventory counting. The inventory officer holds or carries the collection device on their person or vehicle.

An industrial all-in-one machine for scanning equipment can conduct inventory checks “in between” the planned areas during daily work. The actual inventory data scanned is compared with the system data in real time. Any discrepancies will be immediately marked, facilitating managers to quickly trace and adjust. This approach breaks down the inventory checking work into smaller parts, ensuring the accuracy of inventory without affecting operations.

The brain of automated equipment

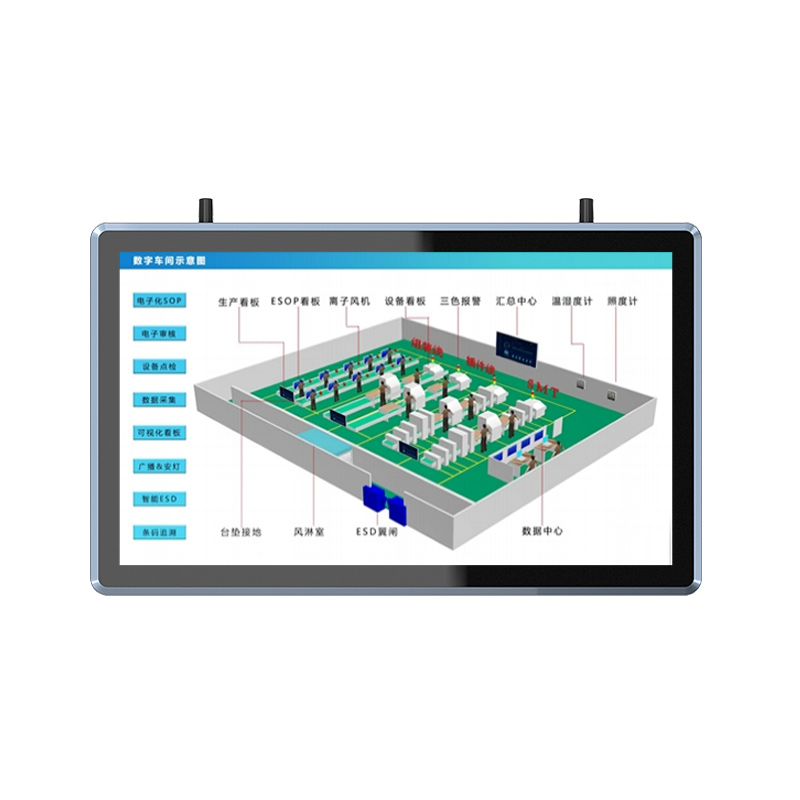

In advanced automated equipment such as Automated Storage and Retrieval Systems (AS/RS), sorting systems (Sorting System), and Automated Guided Vehicles (AGV), the industrial all-in-one machine also plays the role of the control core or monitoring terminal.

It can serve as the scheduling control console for AGVs, monitoring the real-time positions, power levels, and task statuses of all AGVs, and performing path planning and task allocation. On high-speed sorting lines, the industrial all-in-one machine can display sorting statistics, the number of packages at each exit, and the operating status of the equipment, and handle abnormal situations. In the central control room of the automated storage warehouse, the industrial all-in-one machine is the main entry point for operators to interact with the massive and complex stacker cranes, conveyor line systems, and is responsible for issuing inbound and outbound storage instructions and monitoring the operation of the entire system.

Designed for warehouse environments

The warehouse environment poses significant challenges for electronic equipment: continuous vibrations caused by vehicle movement, dust in the air, temperature variations, and possible accidental collisions. The industrial all-in-one machine is specifically designed for such environments. Its sturdy metal casing, anti-vibration internal structure, fanless cooling design, and 1P65 level dustproof and waterproof capabilities ensure that it can work stably and reliably in these harsh conditions for a long time, providing a reliable guarantee for the 7×24-hour uninterrupted operation of warehousing logistics.

In conclusion, the industrial all-in-one machine, by empowering mobile operations, ensuring precise vehicle storage, and controlling automated equipment, has become an indispensable key component in modern intelligent warehousing and logistics centers. It tightly connects people and equipment to the powerful WMS information system, allowing data to flow in real time throughout the warehouse, thereby achieving intelligent, paperless, and efficient warehousing operations, and is a solid foundation supporting the high-speed response of modern supply chains.

Tags: Industrial All-in-One Machine